Sebel's Postura® chairs are meticulously engineered to support student comfort and posture, featuring superior pressure support curves, extra-large lumbar ventilation, and a durable, anti-static design that withstands the rigours of daily classroom use.

Let’s take a closer look at our most popular piece of school furniture in Australia!

Engineered to perfection

Designed and made in Australia, using clever research and genuine science, there’s a reason these high performing chairs have a 20-year warranty.

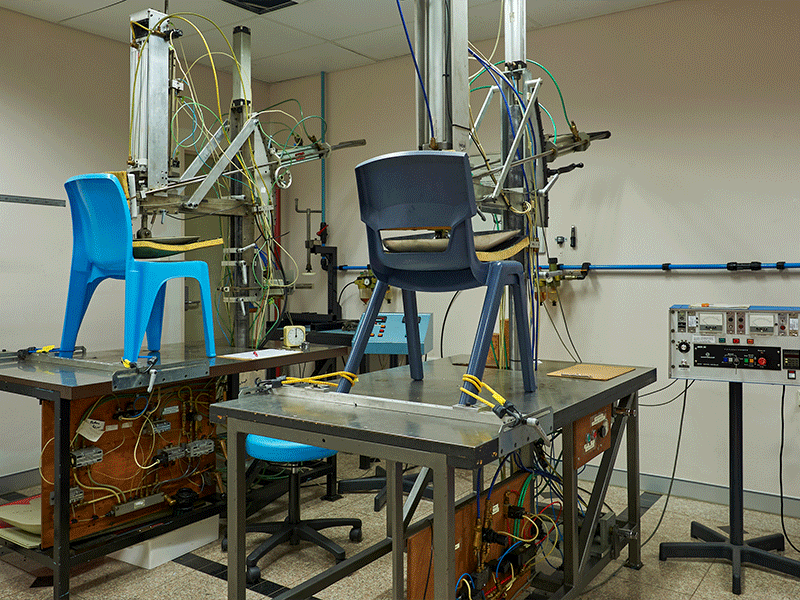

Research has always guided our product design, that’s why we have our very own independent NATA certified testing facility. It is only by the use of this testing equipment to stress-test all furniture components, that we can be absolutely confident that what we make and sell meet all domestic and international standards for strength and durability, giving the long-term service to which all our customers are entitled.

Committed to quality

We hold certificates for various global quality standards, including:

Our manufacturing facilities are ISO 14001 certified, requiring that we reduce harmful effects on the environment and achieve ongoing improvements in environmental performance.

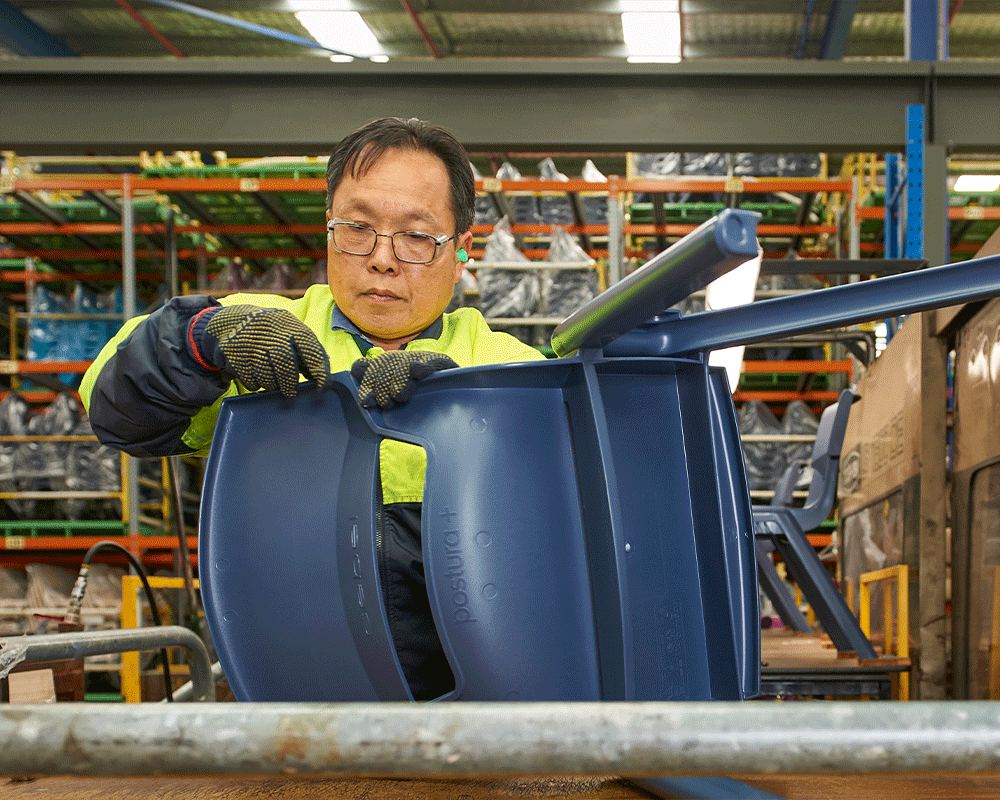

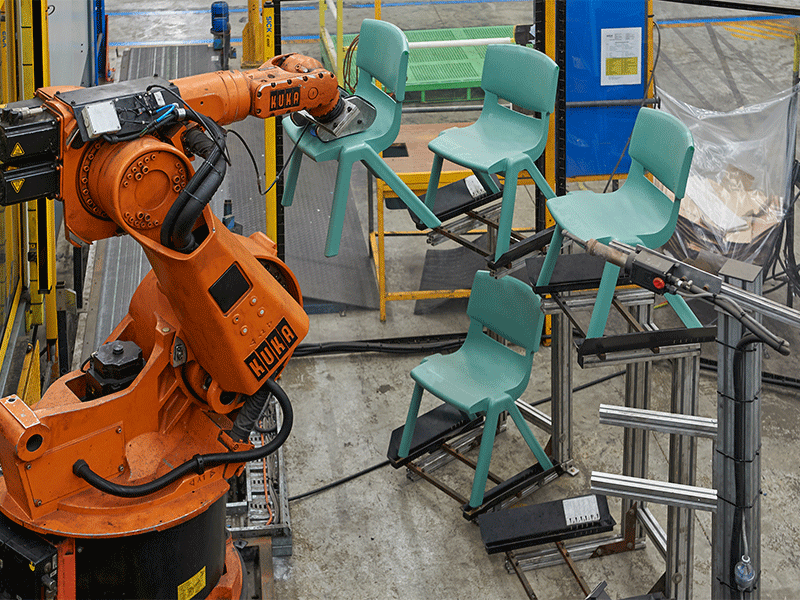

Based in Sydney, our world-class manufacturing facilities adopt best practice lean methodologies making us one of the most efficient producers of high-quality products.

Our factory includes advanced plastic injection moulding machines as well as an upholstery facility and assembly department making lounges, soft furnishings, tables and desks.

We are the pioneers of plastic furniture moulding

We introduced the first-ever monobloc plastic moulded chair, and for almost 70 years we have remained leaders in plastics manufacturing. The name comes from mono- (“one”) and bloc (“block”), meaning an object forged in a single piece, a single piece made possible thanks to injection molding. In modern furniture design, there are many popular variations of monobloc style chairs however, for Sebel this style has been popular not just for the aesthetic but for its ease of use and practicality. Prisons, hospitals, schools and alike all require easy to clean, easy to stack, easy to use educational furniture and healthcare furniture.